Temperature or Process Controllers

Electric heat, while clean, efficient and manageable, can cause damage to product and / or equipment if the temperature is not known, and corrections applied

as required. Best results will be obtained when the maximum and minimum allowable temperatures for a given process are known, and controls selected to

achieve these results.

Types of Controllers:

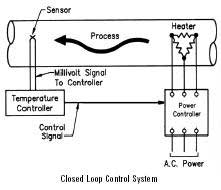

Electronic Controllers

Electronic Controllers receive a signal from a thermocouple or RTD and determine how much heat is needed to control the process. These controllers can range

from very simple dial controllers to complex multi loop PID controllers.

Advantages: Very accurate control, digital displays and flexibility for many applications

Disadvantage: More expensive than some mechanical controls.

Bulb & Capillary and Bi-Metal Thermostats

Mechanical thermostats depend on expanding liquids or metals to open or close contacts in response to temperature changes. Usually, no temperature is

displayed, and a calibrated knob is provided on some models. In mechanical controllers, the sensor is part of the controller.

Advantages: Relatively inexpensive. Some bulb and capillary controls can switch large amounts of current for one or more poles (conductors).

Easy to set up, just turn the knob for the desired temperature.

Disadvantages: On-off controls sometimes have a large differential or dead band. This is the difference in degrees between turn off and turn on.

Your process variation will be greater than the dead band. Bulb and capillary controls do not fail safely. If the capillary tube with the fluid in it becomes

pinched or broken, the thermostat will fail in a heat-on condition, which is a hazard. Bi-metal thermostats, which have no bulb or capillary, typically have

smaller dead bands, and can control more closely. Some will not operate a contactor, which may be needed to switch the higher currents and voltages needed by

the heater. They are often appropriate only for small 120-240V single-phase heaters. Temperature accuracy is inferior to electronic controllers.

Control Modes

Manual: (switch or circuit breaker) For some applications, such as water pipe freeze protection, circuit breakers are turned on in the Fall and

off in the Spring.

Advantages: Low cost, easy operation.

Disadvantages: Possibility of not remembering to turn on equipment in the fall. Energy is wasted when equipment is on if it is not required.

Consider an ambient temperature control to switch the equipment on if the temperature is below 40°F.

Open Loop(Intensity or duty-cycle control):

Includes motor driven timers, infinite control bi-metal relays, and SCR controllers with knobs for setting power percentage. Open loop control does not use a

sensor to determine the amount of heat needed. The control device is set to a specific percent output and switches the output on and off to approximate the

percentage of available heater wattage. Typically used for radiant heat.

Advantages: Low cost, ease of operation.

Disadvantage: Does not compensate for variations in ambient temperatures or incoming product temperatures. Must, in many cases be reset, often

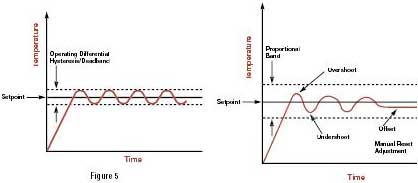

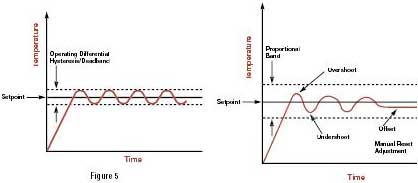

after operator observation of poor process results. On Off (bulb & capillary, bi-metal, or electronic) (See Figure 5)

The dead band (Hysteresis) represents an area about set point in which no control action takes place, and determines at what temperature the output switches

ON and OFF. Narrow deadband settings give control that is more accurate but result in more frequent output switching, which can cause early failure of

electromechanical contactors. On-Off control is available in electronic, bulb and capillary, and bi-metal controls.

Disadvantage: The control is only as accurate as the dead band. Large overshoots will occur with systems with significant lag.

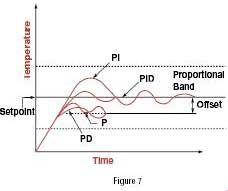

Proportional

Proportional controls reduce the heat output gradually (within the Proportional Band), as the process approaches the set point.

Advantage:

More accurate control than On-off control. In stable conditions (constant load), proportional control can maintain a specific temperature. Since they are

electronic, with wired sensors, such as thermocouples, the control can sense an open sensor and shutdown the process, resulting in a safer control system

than mechanical on-off controls.

Disadvantage: Proportional controls work best on stable processes. They have trouble maintaining temperature during process upsets. Some

proportional controls can switch significant loads with optional high current relays and solid state switching devices.

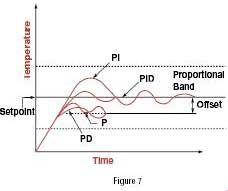

PID

PID (Proportional, Integral, and Derivative) controls, when properly set up (tuned) can manage most situations, including process upsets. Like a Proportional

control, the heat output is gradually reduced while approaching set point, but also with the integral and derivative action can control processes with

varying loads at set point. A wide variety of sensors and parameters ensure a good match of control to process. Many PID controllers have auto tuning

functions that automatically tune to the process.

Advantages:

Good overall control. Since they are electronic, with wired sensors, such as thermocouples, the control can sense an open sensor and shut down the process,

resulting in a safer control system than mechanical on-off control.

Disadvantages: More costly; more set-up required because of greater flexibility. Requires external power controller to switch the load.

Overtemperature Controls(High Limit Controls):

(Bulb & capillary, electronic non-indicating, and electronic indicating). Overtemperature controls provide a safety backup for the primary control and/or the

heaters in case of a problem. The over temperature controller's function is to protect the process or heater. In an over temperature condition the over

temperature controller will shut down the process. The over temperature controller cannot be cleared until the process cools and an operator manually resets

the controller. It is important to use over temperature controllers with a shutdown device such as a contactor to protect the heater process and personnel

from damage or injury.

Power Controls

For small loads (less than 20 amps) some bulb and capillary and electronic controllers can switch the heater directly. For larger loads it is necessary to

use an external power controller. There are various mechanical and solid state power controllers available.

Mechanical Contactors

Mechanical contactors are similar to motor starters. They are capable of switching large amounts of power on an infrequent basis. If turned on and off at a

fast rate (more than 1 or 2 times a minute), mechanical wear and contact erosion will require frequent replacement.

Advantages: Low cost. High switching currents. They do not produce much heat from their operation.

Disadvantages: Contactors are subject to mechanical wear, and produce electrical and mechanical noise.

Snubbers

To minimize electrical noise, snubbers should be connected across each contactor coil minimizing arcing of control relay contacts. A Snubber is an

electronic circuit, which absorbs the inductive kick back of the contactor coil when it turns off.