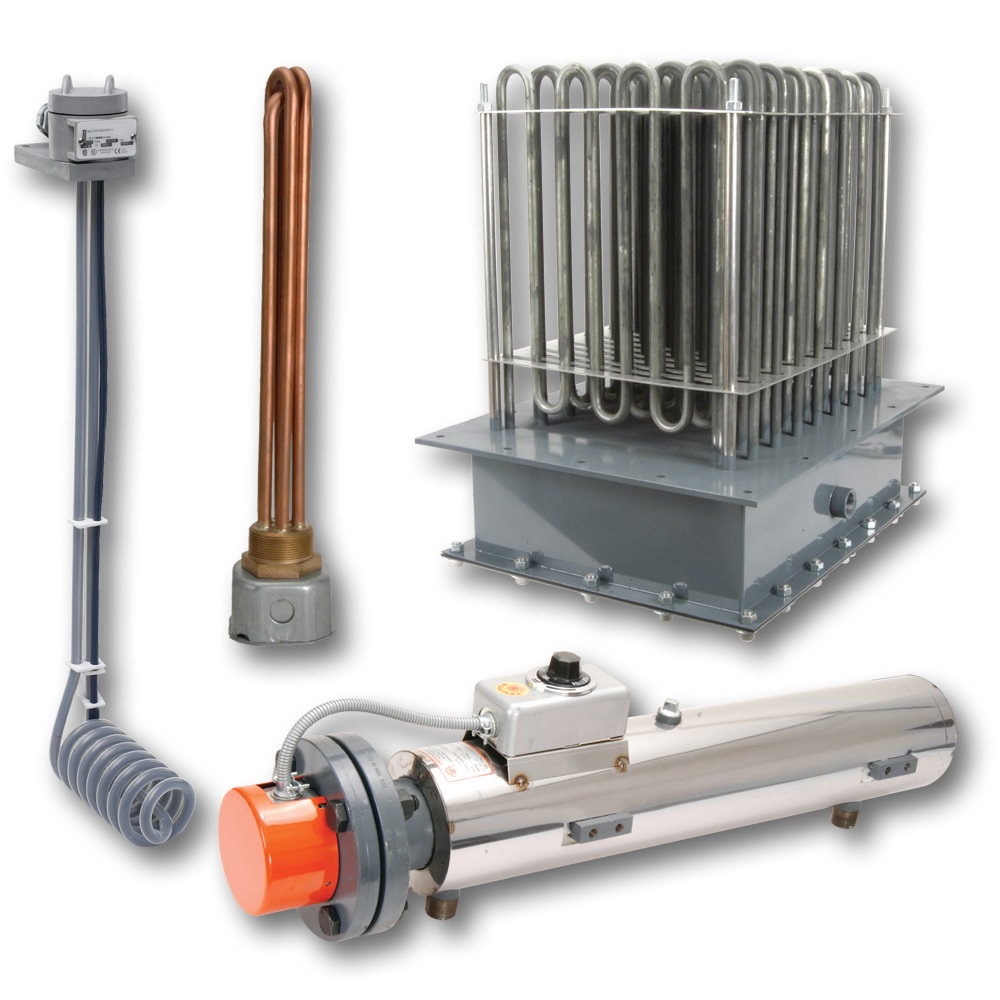

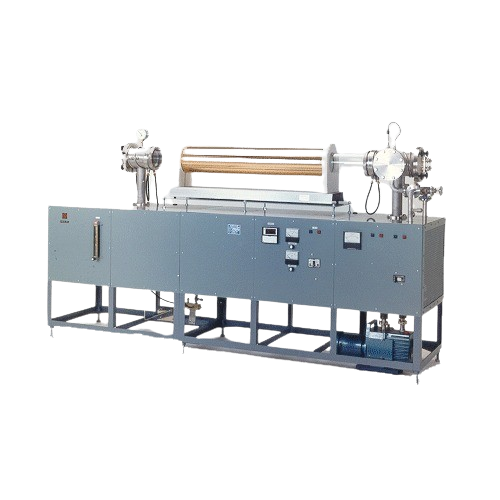

Tubular Heaters

Available in several diameters, lengths and sheath materials, these heaters can be formed into virtually any shape and can be brazed or welded to any metal surface. Choose specific application finned heaters or heaters for runnerless molds.

- Animal Incubators for Prenatal Care

- Ducts

- Epoxy Curing

- Food Service Equipment

- Furnaces

- Fusing Laminated Sheets Together

- Hopper and Silo Heaters - Plastic, Food Agriculture

- Kettles and Tanks

- Ovens - Process, Curing, Food

- Paint and Enamel Baking Equipment

- Plastic Sheet Bending Equipment

- Spas and Hot Tubs

- Steam Tables

- Sterilizers and Autoclaves

- Stretch Wrapping Equipment

- Textile and Chemical Dryers

- Welding Preheat Equipment